Surface finishing is essential in part production. No matter how great the part is, when the finishing process is done correctly, the quality is further enhanced. In order to achieve this, you must know which surface finishing process to use. However, there are many techniques available to use, and each is best suited for specific results. Not knowing the processes can easily result in material waste and inflated costs.

Click Here to Download Our Landing Gear Components Case Study

What is Surface Finishing and What are the Benefits?

In simple terms, surface finishing alters the material—especially metal—to give it certain qualities. This is typically done using an abrasive, which is rubbed against the surface to wear it down. The abrasive has a rough, gritty surface. Using the abrasive, surface finishing removes layers or alters the shape of the material or alters the texture or pattern of the surface of the material.

Surface finishing can change the appearance of the material, make the material water-resistant, help reduce corrosion, make the material more adhesive with paints and other coatings, eliminate surface defects, increase the strength and resistance to wear, and more.

Surface Finishing Process Techniques

Proper surface finishing ensures that the product is high quality, looks better, and lasts longer.

1. Grinding

In this process, an abrasive wheel is used to grind against the material. The wheel rubs against the material and quickly rotates. This rotational movement combined with the abrasiveness of the wheel itself sands the surface of the object to smooth it. This gives the product a more refined look and less susceptible to friction. Grinding is used mainly for cast iron and some types of steel. It can also be used on stainless steel, aluminum, brass, and plastics, though this is less common.

2. Honing

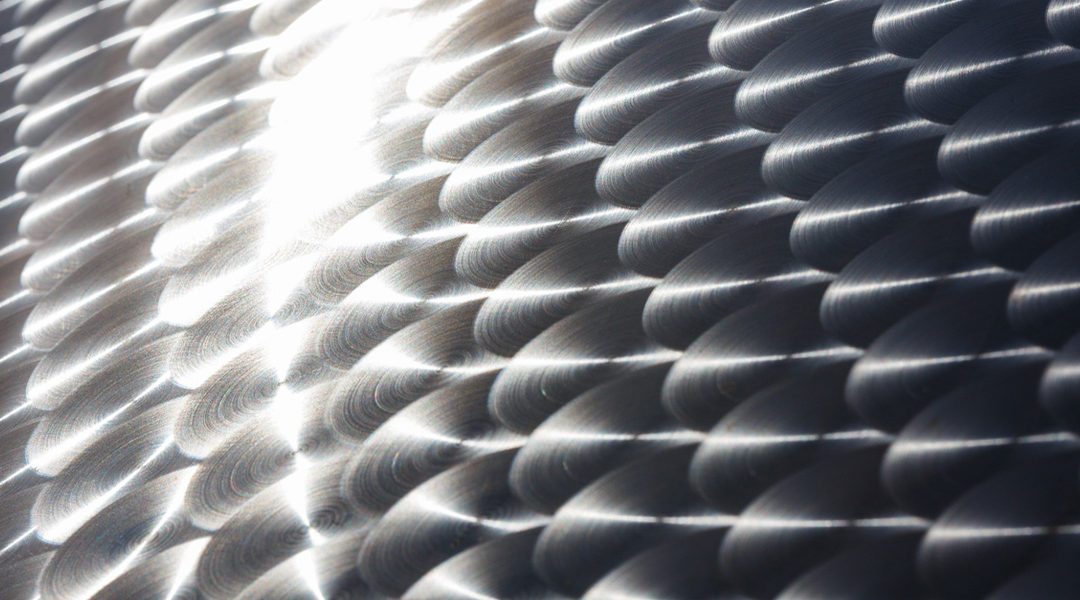

Like grinding, honing uses an abrasive to finish the surface. This process is used to create a pattern on the surface by using abrasive stones and rotating them against the surface to create the pattern desired. Honing is primarily used to improve the geometric form of the surface, but it can also improve the surface itself. The most common application is finishing cylindrical workpieces for internal combustion engines, gears, and air bearings.

3. Polishing and Buffing

These both produce a mirror finish. In addition to this aesthetic appeal, they also prevent rust and corrosion. They use varying degrees of abrasiveness to refine different surfaces, with finer abrasives resulting in the mirror finish. In polishing, the abrasive is glued to the wheel and more pressure is applied on the surface of the material; buffing loosely attaches the abrasive to the work wheel and light pressure is applied on the surface.

The super finishing process puts the parts into a bath of abrasives to remove surface imperfections.

4. Super Finishing

Super finishing is when a fine abrasive is used to wear down a micrometer-deep layer of a complexly shaped workpiece. The abrasive surface and the surface of the material are rotated in opposite directions. Because of the friction produced, this is a heat-intensive process, so a lubricant is used to minimize it. As the process continues, the originally sharp grit on the abrasive becomes dull, and the thin layer has been removed, creating a cross-hatched pattern and fixing tiny errors on the surface.

5. Coating

The coating process can take many forms, and it can be applied in a variety of ways. The coat prevents rust and corrosion. The coat affects the texture, gloss, and color of the material to which it is applied. Some coatings can add water resistance to a material. It could be applied by spraying, rolling, or dipping. Some of the coats include epoxy and urethane, which prevent chemical reactions changing the metal.

Proper surface finishing process is important. Just by understanding the process, you can save costs and time. By taking the time to understand the various processes and your specific needs, you can know what the most suitable finish is for your job. If you have any questions about surface finishing processes, Indiana Precision Grinding is ready to help you!