You’ve designed a part with your CAD, cut the part with your CNC, checked the tolerance, and maybe even had it ground. It’s all set to go, right? Well, maybe not. There is one more step which may be needed to bring your manufacturing to the next level. Let’s talk about superfinishing.

Click Here for our The State of Aerospace Manufacturing Infographic

That’s right, you may not be finished when you finish, you may need to go the extra mile and go for the superfinish. This isn’t some gimmick or scheme, it is a proven way to make products not only look the part, but make them perform better and longer.

But what is superfinishing? Also known as microfinishing, the superfinishing process improves the surface finish and workpiece geometry. The finish removes a layer as thin as 1µm (a micrometer, a one-thousandth of a millimeter). When we remove the micron, we effectively eliminate the smallest imperfections in the material left behind in the cutting process.

How does it work?

There are three types of superfinishing processes: through-feed, with wheels, and plunge. Each works best for particular types of parts.

Through-feed superfinishing is ideal for cylindrical pieces such as piston pins and shock absorber rods. The part is rotated between two drive rollers while a number of progressively finer abrasive stones (usually 4-8) comedown from above to carefully shave away any tiny imperfections.

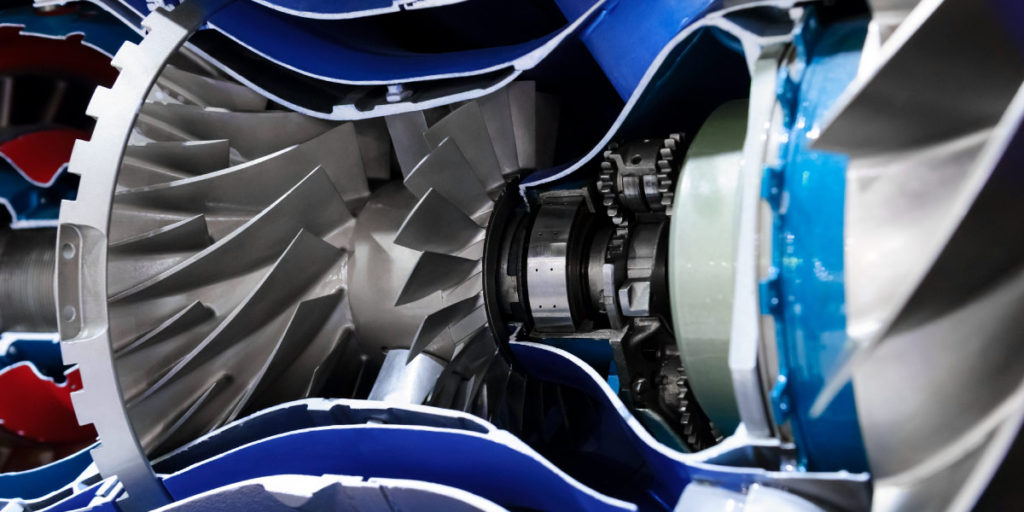

Superfinishing works well for irregularly-shaped parts like aerospace gears.

Superfinishing with wheels is ideal for parts that need to be flat, slightly concave, or slightly convex. The workpiece is held and rotated in one wheel while the abrasive finishing tool is attached to the other. This results in a cross-hatched pattern when the surface, but does not affect performance. If the part and cutting tool are parallel, this produces a flat surface; if the part and cutting tool are held at an angle, this creates a convex or concave surface.

Plunge superfinishing works best for irregularly shaped parts like gears. The original surface is washed with chemical polishing mixture, which forms a coating. Then, the part is put into vibratory finishing equipment, which exposes peaks and imperfections in the material to be removed. The process is repeated until metal parts are smoothed to the required surface quality. Now that the needed quality has been achieved, the chemical mixture is drained away, and a burnishing soap is added into the vibratory machine, which produces the signature mirror-like finish and an amount of rust resistance.

Why is it Needed?

Superfinishing is nothing short of the ultimate finishing process. It consistently and reliably improves the geometry of the surface layer by eliminating any microscopic burrs left behind from the grinding process. This leads to more consistent finishes on virtually any surface finish, all while improving the geometry (roundness and flatness) and part functionality and efficiency. In turn, this improves part functionality. If parts are not superfinished, the burrs left behind create unneeded friction and therefore heat when parts rub together. The heat build-up dulls performance and can cause component or mechanical failures.

Superfinishing does add cost, but when you consider the benefits of the process, it is clear that it is an investment that adds value to the part: it increases part life, decreases wear, allows for superior sealing capabilities, and closer tolerances.