When we think of polishing metal and aerospace parts, we sometimes dismiss the process as purely aesthetic: form over function, if you will. A polishing process can remove directional lines and produce a uniform luster. Great, but what utilitarian purpose does that serve for the parts themselves? How does the polishing or buffing process make aerospace parts better at their job? Let’s find out.

Out of round parts are difficult to grind, Click Here to learn how we did it.

Let’s start by talking about polishing on the surface-level. Polishing makes cleaning the part a lot easier. This is because polishing reduces contamination and the chances of anything adhering to the surface. Because of this, polished parts don’t take nearly as long to clean: potentially cutting cleaning time in half. Even if you’re working with stainless steel, polishing helps the metal resist oxidization and degradation. The polishing process acts as something of a buffer between the part and any outside forces that can make the part dirty.

The main benefit polishing can have on the quality of the parts is an increased durability. We touched on this above, but because the parts are more resistant to contamination, they are less susceptible to wear and corrosion. Whether the polishing process is done through chemicals or abrasives, the metal will last a lot longer than an untreated metal.

Polishing also has enhanced mechanical properties to offer for parts. The part is subject to less friction and surface drag, which makes for smoother movement. It also relieves stress on the metal’s surface and reduces the galling of threads on stainless and carbon steel. Additionally, fatigue strength isn’t reduced and in fact can be improved by using a particle-blasting process.

Certain polishing techniques can also reveal flaws in metal surfaces, allowing for the additional metalworking of metals and alloys to properly shape both radii and sharp edges.

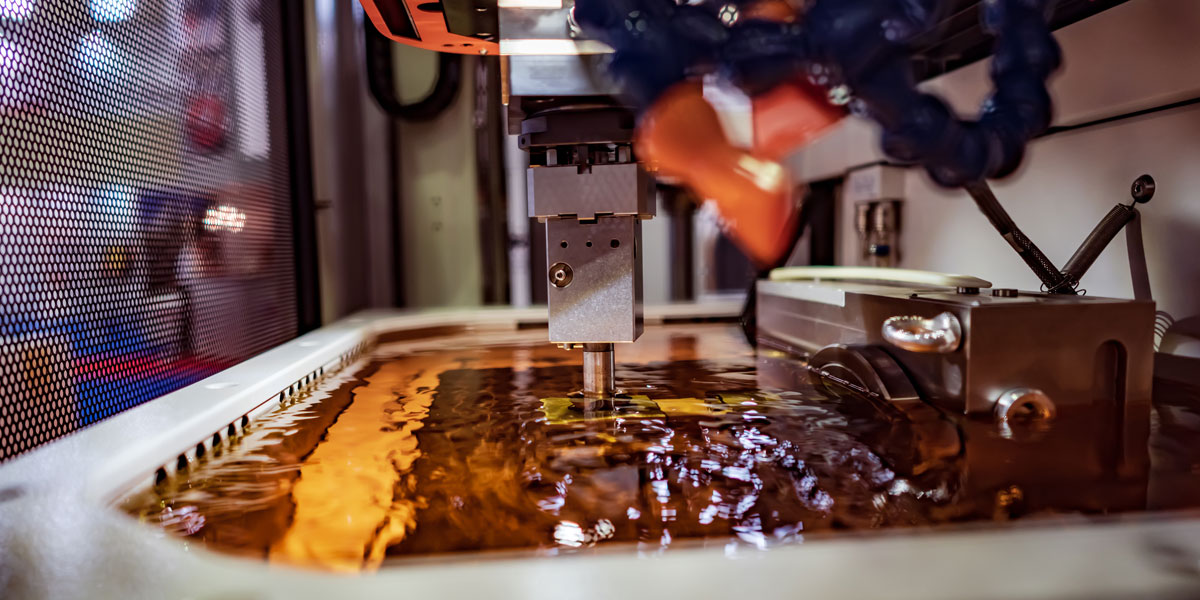

An electrolythic bath uses an electrical current to polish metal.

There are two general types of polishing: traditional and electropolishing. Naturally, both have their benefits. Traditional grinding is akin to grinding: it uses abrasives to achieve the desired finish. Different materials need different grits to achieve this. Finer finishes need higher grit: if the goal is to buff out fine marks, 600 grit wheels are ideal (More information on Different Types Of Grinding Wheels can be found here). Wax and kerosene can be used to lubricate and cool the workpiece.

Electropolishing is done by attaching two electrodes, an anode and a cathode, to the workpiece. Then they are connected to a direct current power supply. Then, the piece is given a electrolytic bath. This produces an electrical current which causes any impurities and irregularities to fall away.

Polishing is used to enhance and restore metal parts. If you aspire to get the best out of your aerospace parts, polishing and grinding processes are exactly what you’re looking for. If that is indeed what you’re looking for, the team at Indiana Precision Grinding wants to help you achieve that.