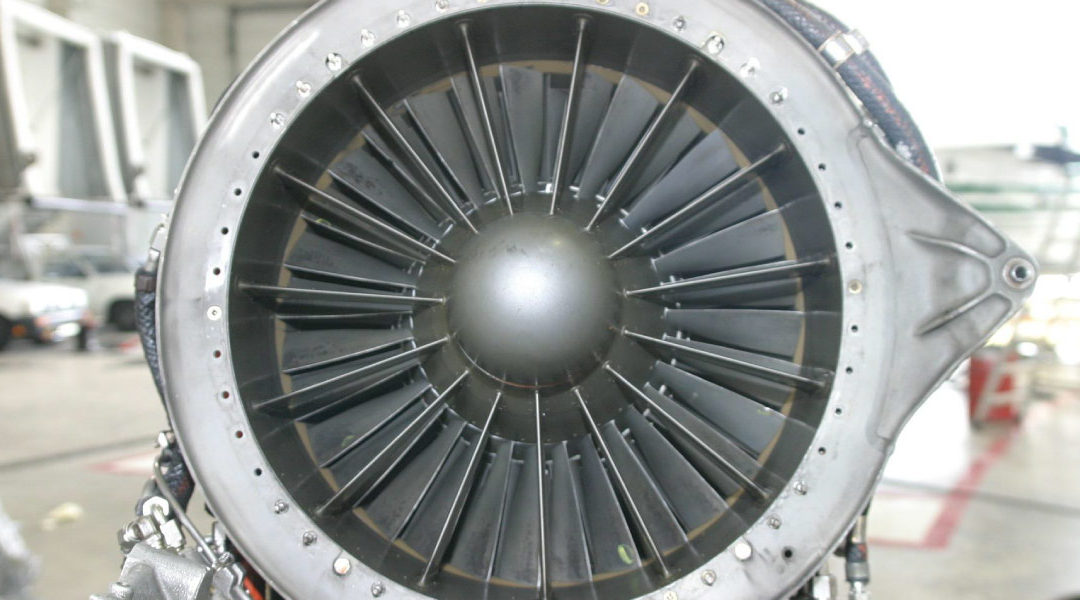

When producing aerospace parts, we know that the design and cutting of metal parts is an expensive process. The aerospace sector is among the most highly regulated and complex industries, so creating parts for this industry is an investment in both time and monetary resources. Parts must be tested to ensure they are fit for use. So, when it comes time to test the parts, you don’t want to destroy one to find out if there are problems with any others in the patch—throwing away all time and energy that went into developing the part. The solution lies in nondestructive testing (NDT): and among the many nondestructive testing methods, nital etch inspection is one of the most efficient and reliable testing methods.

Ten Centerless Grinding Facts that may Surprise You

What is Nital Etch Inspection?

Etching is a series of nondestructive tests which forms a crystalline structure on the surface of the workpiece. This creates a visible contrast between the parts of the metal that are structurally sound on those that are not. Nital etching is a specific surface test, using a mixture of nitric acid and alcohol. Since nitric acid is a strong oxidizer and alcohol acts as a fuel, it’s dangerous to handle the nital solutions without proper knowledge and equipment, only experts should perform the test.

Why Does It Matter?

Performing an etching test like nital etch is an important process for aerospace manufacturers because the metalworking process introduces a lot of heat. As much cooling as manufacturers use, it’s still easy to burn the workpiece. This is an issue because a burned area of metal may damage the whole part’s properties and structural integrity—shortening the part’s lifespan or even cause a critical failure. This is a particularly tricky problem because sometimes these burns are invisible to the naked eye.

How does Nital Etch Inspection work?

When the test is performed, the nital solution is applied to the substrate. Since the burned areas of the metal will be softer and have a different chemical structure, the etching solution will burn faster, leaving behind a darker area compared to the structurally-sound areas. The procedure can be used for a variety of parts including shafts, gears, splines, bearings, and more.

Specifically, nital etch is used to identify:

- Over tempering

- Localized re-tempering

- Re-hardening

- Localized discontinuous carburization

- Decarburized surface layer.