Oct 22, 2020 | Metalworking

With impressive precision and ability to identify cracks, corrosion, and material degradation, radiographic testing has been a widely accepted method of nondestructive testing for a wide variety of industries including aerospace, automotive, and military. So, what...

Sep 24, 2020 | Aerospace, Metalworking

For years, OEMs used hard chrome plating to provide wear protection on a wide variety of parts and components for everything from vehicles to gun barrels—so it probably wouldn’t be too surprising to learn that the aerospace industry relied pretty heavily on...

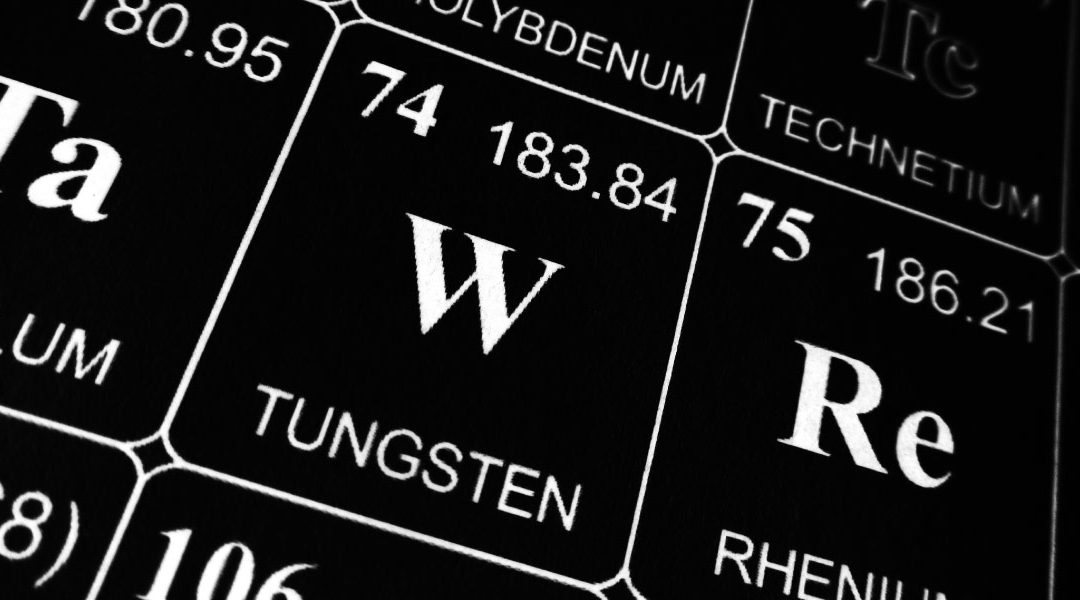

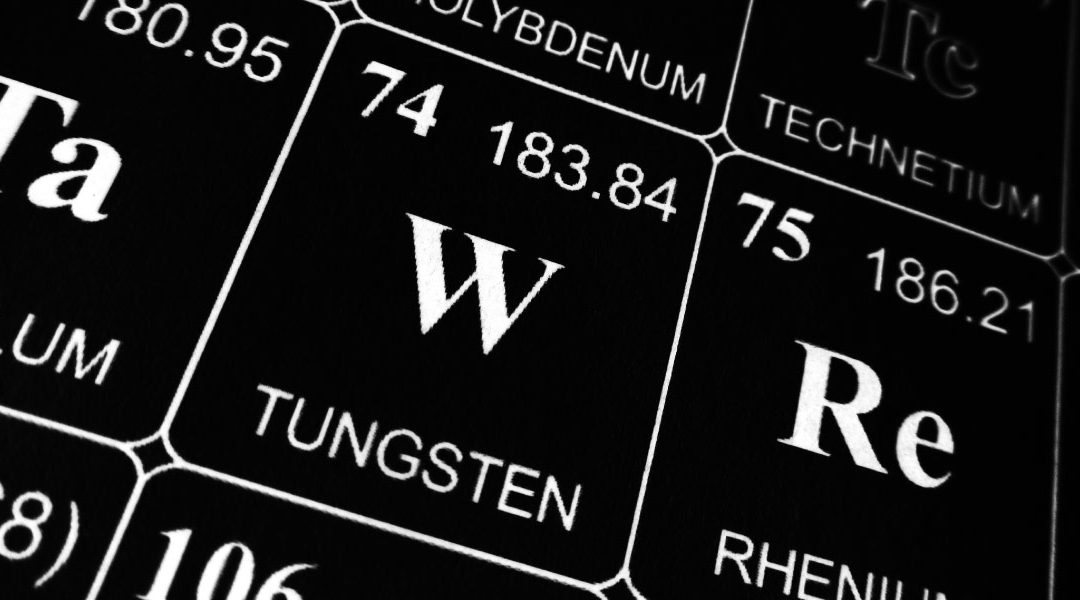

Aug 27, 2020 | Aerospace, Metalworking

When we talk about air and spaceflight, the materials used to construct the aircraft and parts are critical. Different metals have different properties which make them more suitable for certain applications. Let’s talk about some of the common metals used in...

Aug 12, 2020 | Metalworking

When it comes to precision grinding, there are so many specific types of processes that it can be difficult to fully comprehend the seemingly endless number of them. Every grinding process brings with a certain complexity, so they each require a thorough understanding...

Jul 16, 2020 | Metalworking

When it comes to the aerospace industry, there is really no room for compromise. The materials used must be able to withstand the extreme conditions of air- and spaceflight. Being in the metalworking and aerospace industry for 45 years has taught us a few lessons,...

Jun 24, 2020 | Aerospace, Metalworking

It’s no secret that designing, crafting, finishing, and installing aerospace parts is a challenging prospect requiring the highest levels of concentration, skill, and technology to achieve. As if these weren’t complicated enough, there are additional...