For centuries, humankind dreamed of leaving the ground and exploring the realms of the sky. Although Leonardo da Vinci aspired to create a flying machine, his dream wouldn’t become a reality until four centuries later. There are many fascinating characters woven into the story of how man created flying machines. Here’s a quick history of aerospace and aerospace manufacturing.

Read About the State of Aerospace Manufacturing

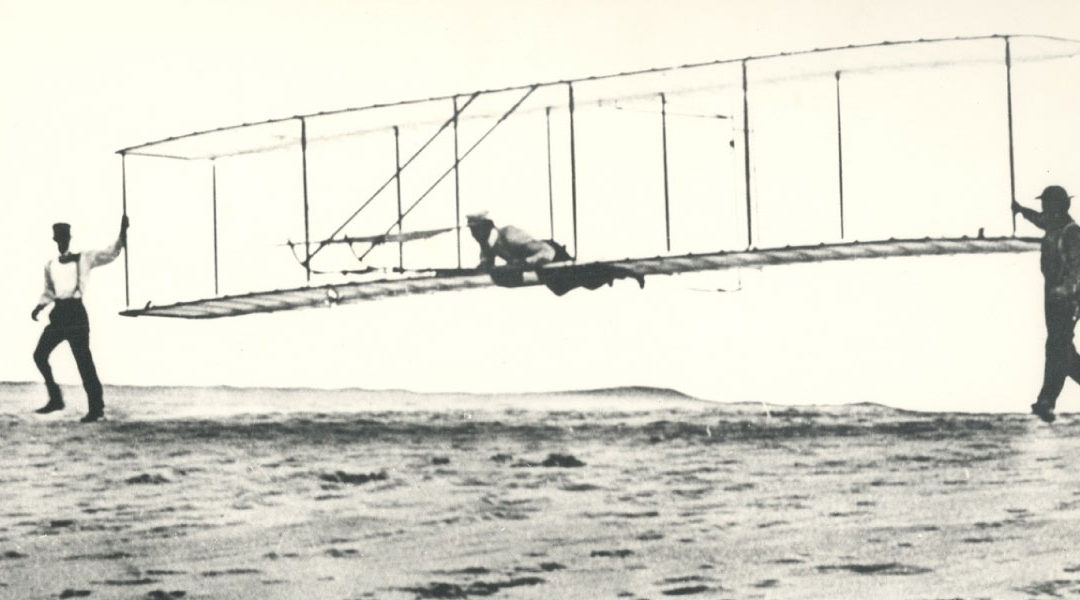

Orville and Wilbur Wright testing their flying machine at Kitty Hawk, North Carolina.

No recounting of aerospace manufacturing history would be accurate without this famous milestone. On December 17, 1903, Dayton, Ohio natives Orville and Wilbur Wright made a four-mile flight just south of the small-yet-internationally-famous town of Kitty Hawk, North Carolina. The race to create faster, higher-flying machines was officially on.

To say the advancements in aerospace were rapid would be an understatement. By 1911, plane races from one city to another were being conducted. Also, the lines representing the aerospace industry and military sectors were drawing towards their inevitable intersection. During World War I, airplanes found their application in combat, though not in the way you might expect: the War was fought primarily with trench warfare. Pilots took to the air to scout their opponents from above, looking for the depth and breadth of enemy trenches and for any strategic weaknesses. Sometimes, these planes were armed, but not in the way you might expect: it wasn’t the planes that carried the guns, but the pilots would sometimes be equipped with handguns or propaganda which was dropped on enemy troops. Air-to-ground bombing and dogfighting were young technologies, but they were being developed during the war.

By the end of World War I, United States Army Brigadier General Billy Mitchell—who would later earn the moniker Father of the US Air Force—boldly, controversially, and ultimately accurately made a prediction:

“The day has passed when armies on the ground or navies on the sea can be the arbiter of a nation’s destiny in war. The main power of defense and the power of initiative against an enemy has passed to the air.”

Between global conflicts, though, the aerospace manufacturing sector declined. Military contracts were largely cancelled, but military aircrafts were being repurposed for civilian use such as passenger flight and mail service. Biplanes fell out of favor as lighter monoplanes were made with aluminum alloy frames.

As mentioned, the aerospace economy was down until Charles Lindbergh got in the cockpit of the Spirit of St. Louis and flew over 33 hours from New York to Paris in 1927. The industry thrived, riding the “Lindbergh Boom” to a threefold increase in value, until the Great Depression began in 1929.

The Second World War brought more investment and technology back to aircrafts: planes were faster and built to withstand those higher speeds. Planes were also armed with machine guns, leading to the high-speed dogfighting we think of today.

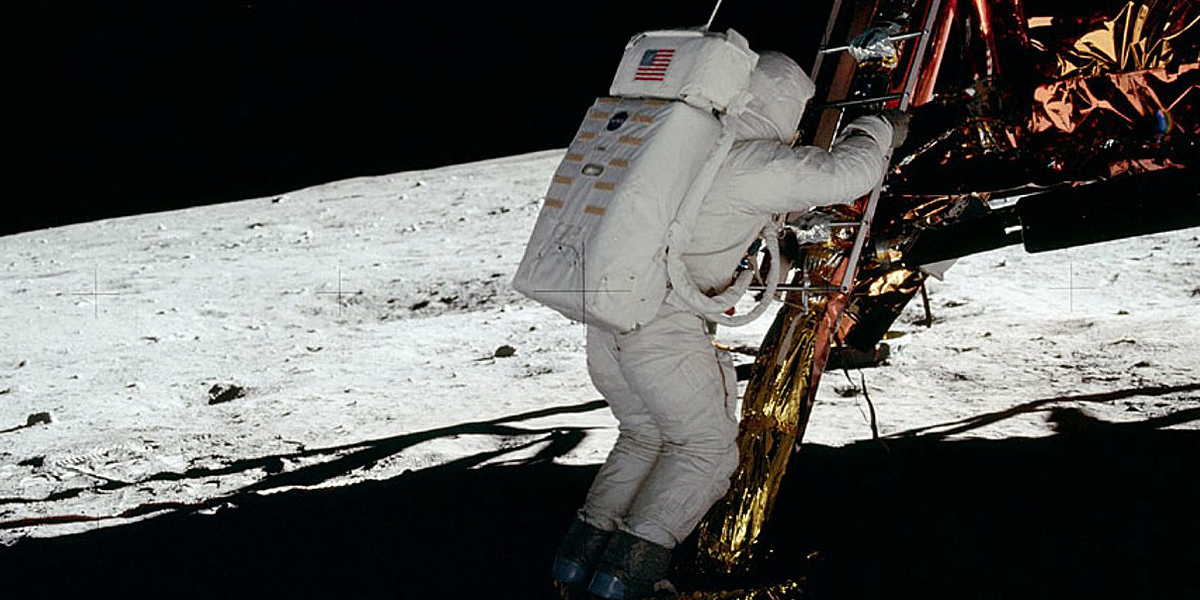

In 1969 the United States landed astronauts on the moon.

With technology pushing the limits of the atmosphere, the next step was clear: what could we do beyond the planet? The Soviet Union launched Sputnik into orbit on October 4, 1957, the Space Race began. The United States responded with the Corona program in 1959, which served much the same purpose as airplanes did in World War I: surveying the military activities of its Cold War nemesis. The Soviets upped the ante, launching Yuri Gagarin into space aboard a Vostok 1 spacecraft in 1961. Of course, we know how the Space Race ended, with Neil Armstrong, Buzz Aldrin, and Michael Collins flying and the former two walking on the moon on July 20, 1969.

But aerospace’s fascinating does not end there. All around the world, manufacturers still pursue their tireless mission to design, build, and fly faster, more efficient, and overall better aircraft. They rely on the best parts available to make that dream a reality. That’s where we come in. The entire team at Indiana Precision Grinding is proud to be a part of aerospace manufacturing’s rich tradition and we look forward to being a part of its bright future.